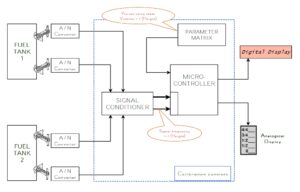

APS capacitive fuel gauging consists in 4 probes and a central control unit. By mean of 2 probes per tank, it allows controlling the fuel level and displays the result on digital or analogical display.

Linearity is maintained by programming the tanks into an electronic memory that is used as reference by the micro-controller.

Moreover, signal conditioner integrates a monitoring section that continuously checks probes output frequency, and any deviation of pre-set values triggers a warning signal.

Implantation is quite simple because probes do not require any calibration. Level adjustments are performed on conditioner by 4 potentiometers.

This system is is presently certified and in production.

Key features

- Optimised design-to-cost architecture

- 28 Vdc input

- H-bridge command for brushed machine

Applications

- Aviation gasoline

- Kerosene gauging

Specifications

Electrical

VDC or digital display

Physical

Probes

Electrical

Physical

Environmental

-40°C to +85°C (extended during 1 hour operating conditions)

Eads-Socata TB range (TBA-TB10-TB20-TB21-TB200-…)

Note: Due to continuous process improvement, specifications are subject to change without notice