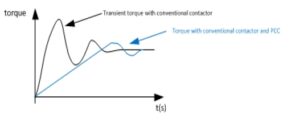

The PCC controls the transient starting torque provided by the DC machine to the engine.

- Maximum torque is no longer dependent on electrical source, battery temperature, wiring…

- Applied torque is a slope (no longer a step) to avoid any shaft transient oscillation leading to high torque overshoot (up to 2X in case of poor damping)

- Provides smooth starting torque

- Accurate control of the peak torque provided by the S/G or the starter

- Limits transient under-voltage on HC DC Bus thanks to inrush current limiting

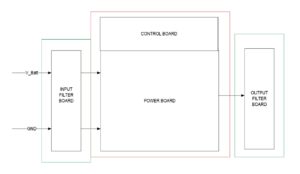

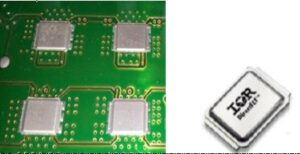

- In order to optimize the volume of DC/DC converter, we choose DIRECTFET Technology withwith Cooled Direct FETTM on PCB

- Control : mixed analog + CPLD

- Efficiency > 90%

Key features

- 3 phases 115 Volts alternating current(VAC)-variable frequencypower input

- Active power factor corrector

- Sensorless motor drive

Applications

- Airbus civil aircraft

- Boeing civil aircraft

Specifications

Electrical

Input voltage

V= 10 to 32 VDC

Output current

500 A

Starting Duration

Three consecutive starts without rest time

High switching frequency (>150 Khz)

Standard protection (short circuit, overheating, overvoltage, EMI)

High switching frequency (>150 Khz)

Standard protection (short circuit, overheating, overvoltage, EMI)

Physical

Width

200 mm

Height

60 mm

Depth

150 mm

Weight

1 900g

Environmental

Temperature

-45°C to +70°C (normal operating conditions)

Certification approvals

ABD 100

EN 2282

DO 160- sect 10

EN 2282

DO 160- sect 10

Note: Due to continuous process improvement, specifications are subject to change without notice